MicroPore ExtendAirCartridge (EAC)

Product details

Who are MicroPore

Micropore, Inc. located in Elkton, Maryland, USA, packages fine powder chemistries into solid absorbent cartridges that are used to absorb carbon dioxide in rebreathing and life support systems. Founded in March of 1997, Micropore’s solid cartridge technology out performs traditional granular CO2 absorbents. The patented technology is the first major advance in CO2 absorbent technology in over 100 years, providing superior performance advantages over existing granular absorbents.

The CO2 absorbent cartridges are marketed under the ExtendAir® and SpiraLith®CaTM brand names and are used for life support in the fire-fighting, medical, dive, submarine, and military markets.

Berry compliant all Micropore products are manufactured in their USA factory.

What is ExtendAir®

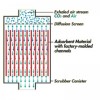

ExtendAir® is the brand name for Micropore's CO2 absorbent filtration cartridges and canisters. Micropore uses the same basic chemistry found in granule CO2 absorbents, calcium hydroxide and a small amount of potassium and sodium hydroxide (chemical composition information can be found on material safety data sheet). Micropore blends these chemicals along with a small amount of polyethylene (plastic binder) into a molded sheet of material with raised ridges on one side and flat sheet on the other side of the material. The sheet is then wound (rolled) on a plastic center core to a cylindrical cartridge meeting diameter and height requirements specific to the ExtendAir® compatible canister. For optimised Work of Breathing (WOB) and scrubber duration performance the scrubber canister needs to be designed around the EAC and not the other way around. Cartridges are kept tensioned as a cartridge roll of material with a heat-staked clear film wrap. The EAC features high CO2 absorbent performance (liters CO2/lb absorbent) and low resistive effort (reduced WOB for the diver) in addition to adding safety via its molded sheet and elimination of caustic dust entering the breathing loop.

The ExtendAir® canister replaces the granular canister as a safer and higher performing option for military rebreather uses; one that is safe for filling within submarines, or in wet environments and any operation that needs to mitigate the risk of caustic cocktails. The efficiency of an EAC canister also eliminates the need for a neoprene insulator at colder water temperatures as found on some military rebreathers, further easing deployment logistics.

In the Incursion family of Open Safety rebreathers, a 2.2kg Micropore EAC offers comparable scrubber duration, to 2.6kg of granual Drager DiveSorb Pro absorbent.

The Micropore EAC achieved CE certification in the Open Safety range of Commercial, Military and Recreational rebreathers in 2011 to EN14143. Independent of Drager, with US Navy request and cooperation, Micropore Inc designed a solution to use its patented Extendair® CO2 absorbent technology in the Drager MK25 rebreather. Engineering Change Proposal XE012 for the MK25 Mod 2 UBA approved 2 Sep, 2014.

Micropore EAC SM0655C for military and professional use

The SM0655C is the new model number of the SM-0801C for military rebreathers.

ExtendAir® CO2 absorbents have been developed for use in military, commercial and recreational rebreathers. The main advantages of the cartridge technology are:

Single use packaging

Lack of dust compared to granules

Water tolerance: no immediate "caustic cocktail" when wet

Lowest work of breathing possible

Excellent shock and vibration resistance

Micropore Extendair Cartridge, 125mm x 195mm with wide central bore (Model SM0655C).

The absorbent has many national defence applications including use for military Special Operations rebreathers, emergency and primary atmospheric control on submarines. Compared to the traditional granular carbon dioxide absorbents, it makes breathing up to 40% easier and provides up to 25% longer life support for any given weight.

ExtendAir® absorbent does not have the safety, storage, and loading problems associated with the granular absorbents. Granule absorbents form a powder when subjected to the shocks and vibrations of regular transportation, storage, and in-use scrubbing. The powder creates a dangerous chemical dust and settling in the scrubber canister, shortening the scrubbers’ duration and making breathing more difficult. ExtendAir® cartridges do not suffer from this type of degradation during transportation, storage or use. In addition, ExtendAir® absorbents for rebreathers offer a significantly reduced ‘caustic cocktail’ when compared to other absorbents. Operationally, it is superior since it takes mere seconds to load, reduces training time, is more reliable, and its single use packaging eases deployment logistics.

ExtendAir® cartridges are approved for use in combat diver rebreathers by the US Navy and several EU countries’ Special Forces. The absorbent is FDA approved for medical oxygen delivery systems.

ExtendAir® cartridges (EACs) are supplied in boxes of 4, and shipped with a minimum order quantity fo 8 EACs. On pallets, 384 EACs, comprising 96 boxes of 4, can be loaded onto a 1.2 x 1.2 x 1.6m pallet (weight 890kg).

Diver Features and Benefits:

Diver Safety: 70% less caustic even after 5 minute flood

No Dusting, No Spillage:

No absorbent gets in the breathing loop.

Platform friendly (submarine, rib, ships quarters, etc.)

Eases maintenance logistics

Storage: Absorbent is stored with rebreather instead of separately in bulk containers; single-use packaging also reduces wasted absorbent

Diver's breathing workload is reduced by 15% (MK25)

Canister loads 3-5 times faster

Excellent tolerance to storage, shock, vibration

No settling: Consistent scrubber duration; no absorbent bypass or channeling

Significantly reduced Operational Risk assessment for operation

ExtendAir technology for Submarines

Lithium hydroxide (LiOH) absorbent is used for both active CO2 absorption (powered scrubber systems) and passive CO2 absorption (hanging curtains). Lithium hydroxide outperforms other absorbents at low temperature or elevated pressure such as in disabled submarine, DISSUB. ExtendAir® LiOH curtains provide 55% increase in absorbent weight per given storage volume compared to granular LiOH. What this means to a submarine crew is increased life support duration without sacrificing the limited available space. ExtendAir® curtains outperform granular calcium hydroxide absorbents by as much as 4 times depending on temperature and pressure. The US Navy has approved Micropore’s ExtendAir® curtains for use onboard their submarines (part number RM-0601C, NSN 6810-01-560-3015). The UK Royal Navy approved ExtendAir® curtains for their submarines (OM-0612K, NSN 4240-01-543-3287). Independent testing by multiple Navies (US, UK, Italy, the Netherlands, Singapore, Canada) has confirmed superior performance by Micropore® curtains.

Care and Storage Instructions

- After use, wash in fresh water and allow to dry in a well ventilated area out of direct sunlight

- Store in a well ventilated dry area away from direct sunlight